Subcontracting

Many industries demand products with components of near-perfect quality, in terms of choice of materials, dimensions, surface finishes and geometric complexity. Petitpierre offers its know-how in a wide range of fields: wire erosion, electroerosion sinking, CNC, micromechanics…

Turning CNC milling

Mastercam and Gibscam

OKUMA MULTUS U3000

6-axis machining center

Features

- Main spindle: 4,200 rpm

- Return spindle: 4,200 rpm

- Milling spindle: 20,000 rpm

- Machining diameter: 80 mm

- Machining length: 1’100 mm

- 80-tool changer

- LNS Quick Load servo III feeder

- 80-bar high-pressure watering

OKUMA MULTUS B200 II

6-axis machining center

Features

- Main spindle: 5,000 rpm

- Return spindle: 5,000 rpm

- Milling spindle: 12,000 rpm

- Machining diameter: 65 mm

- Max. machining diameter: 600 mm

- Machining length: 750 mm

- 40-tool changer

- LNS QUICK LOAD SERVO III bar feeder

OKUMA MULTUS B200 II

6-axis machining center

- Main spindle: 5,000 rpm

- Return spindle: 5,000 rpm

- Milling spindle: 12,000 rpm

- Bar machining diameter: 65 mm

- Max. machining diameter: 600 mm

- Machining length: 750 mm

- 40-tool changer

- LNS QUICK LOAD SERVO III bar feeder

CNC milling

Mastercam and Gibscam

The Petitpierre team can offer you a demonstration at its Cortaillod premises, to show you how these machines work.

FEHLMANN VERSA 645 Linear

5-axis machining center

Features

- Spindle: 30,000 rpm

- Rotary table Ø 400 mm

- X/Y/Z strokes: 350 mm x 500 mm x 300 mm

- 86-tool changer

- Palletizing 60 pallets

OKUMA GENOS M460 V-5AX

5-axis machining center

- Spindle: 15,000 rpm

- Rotary table Ø 400 mm

- X/Y/Z strokes: 760 mm x 460 mm x 460 mm

- 32-tool changer

OKUMA MB46 VAE

4-axis machining center

- Spindle: 15,000 rpm

- X/Y/Z strokes: 760 mm x 460 mm x 460 mm

- 48-tool changer

- Axis A divider

CNC Turning / Screw-cutting

Mastercam and Gibscam

OKUMA LB300-MY Tower

- Turning spindle: 4,500 rpm

- 12-tool milling spindle: 4,500 rpm

- Bar machining diameter: 52 mm

- Max. machining diameter: 530 mm

- Machining length: 500 mm

- LNS 52HS4.4 bar feeder

CITIZEN CINCOM L32-XII bar-turning machine

- Main spindle: 8,000 rpm

- Return spindle: 8,000 rpm

- Bar Ø: 32 mm

- Max. turning length: 320 mm

- Main spindle: Comb 9 tools, 3 of which rotate; B axis 4 tools and

- 3 front-mounted tools

- Backworking spindle: 9 driven tools; B axis 4 tools

- LNS EXPRESS 226 bar feeder

Wire EDM / Sinking

EF Agie Charmilles CUT2000S

- Two-wire erosion machine

- Accuracy ±0.002mm

- Wire from 0.05 to 0.30mm

- Max. part size: 250x350mm

- Max. part thickness: 250mm

- Maximum part weight: 800kg

2x EF Agie Charmilles VERTEX 2F

- Accuracy ±0.002mm

- Wire from 0.03 to 0.33mm

- Max. part size: 250x350mm

- Max. part thickness: 250mm

- Maximum part weight: 800kg

EE Agie Charmilles FORM S 350

- Sinker erosion machine

- Table size: 500x400mm

- Axis travel X: 350mm Y: 250mm Z: 250mm

- Speed: 0 to 100 rpm.

- Maximum part weight: 500kg

- 16-tool loader

- Measurement resolution: 0.05µm

EF Agie Charmilles Progress VP2

- Accuracy ±0.002mm

- Wire from 0.10 to 0.33mm

- Max. room dimensions: 750x550x250mm

- Max. part thickness: 250mm

- Maximum part weight: 450kg

EF Agie Charmilles Progress V2

- Accuracy ±0.002mm

- Wire from 0.10 to 0.33mm

- Max. room dimensions: 750x550x250mm

- Max. part thickness: 250mm

- Maximum part weight: 450kg

EE Agie Charmilles DRILL20 EDM milling machine

- Table dimensions: 300x200x300mm

- Electrode: ø0.3 to 3mm

- Max. drilling depth: 200mm

- Max. weight: 300kg

SARIX SX80 HPM Micro-erosion Micro-milling

- Ømin. 0.04mm

- Accuracy: ±0.002mm

- Displacement accuracy: ±0.005mm

SARIX T1-T4 spark erosion milling machine

- Ømin. 0.12mm

- Accuracy: ±0.002mm

- Displacement accuracy: ±0.005mm

Grinding / Planishing

Cylindrical grinding machine

Studer S21

- Thread grinding from S0.8

- Resolution: 0.0001mm

- Distance between tips: 400mm

- Tip height: 125mm

- Max. stroke X axis: 254mm

- Speed: 0.001-10’000 mm/min.

- Max. Z axis travel: 483mm

- Speed: 0.001-20’000 mm/min

Tailstock

- 1 Straight grinding wheel ø400mm

- 1 Wheel ext 30° ø350mm

- 1 spindle for internal grinding wheel 60’000 rpm

- Precise servo-controlled C axis

Glider

Jakobsen 1026F

- Stroke: 700mm x 310mm

- Grinding surface: 650mm x 300mm

- Maximum distance between table and spindle axis: 550mm

- Longitudinal speed: 30m/min.

- Grinding wheel dimensions: 200mm x 76.2mm x 25mm

- Spindle speed: 1400 to 1700 rpm

Vertical glider

Hugi F160

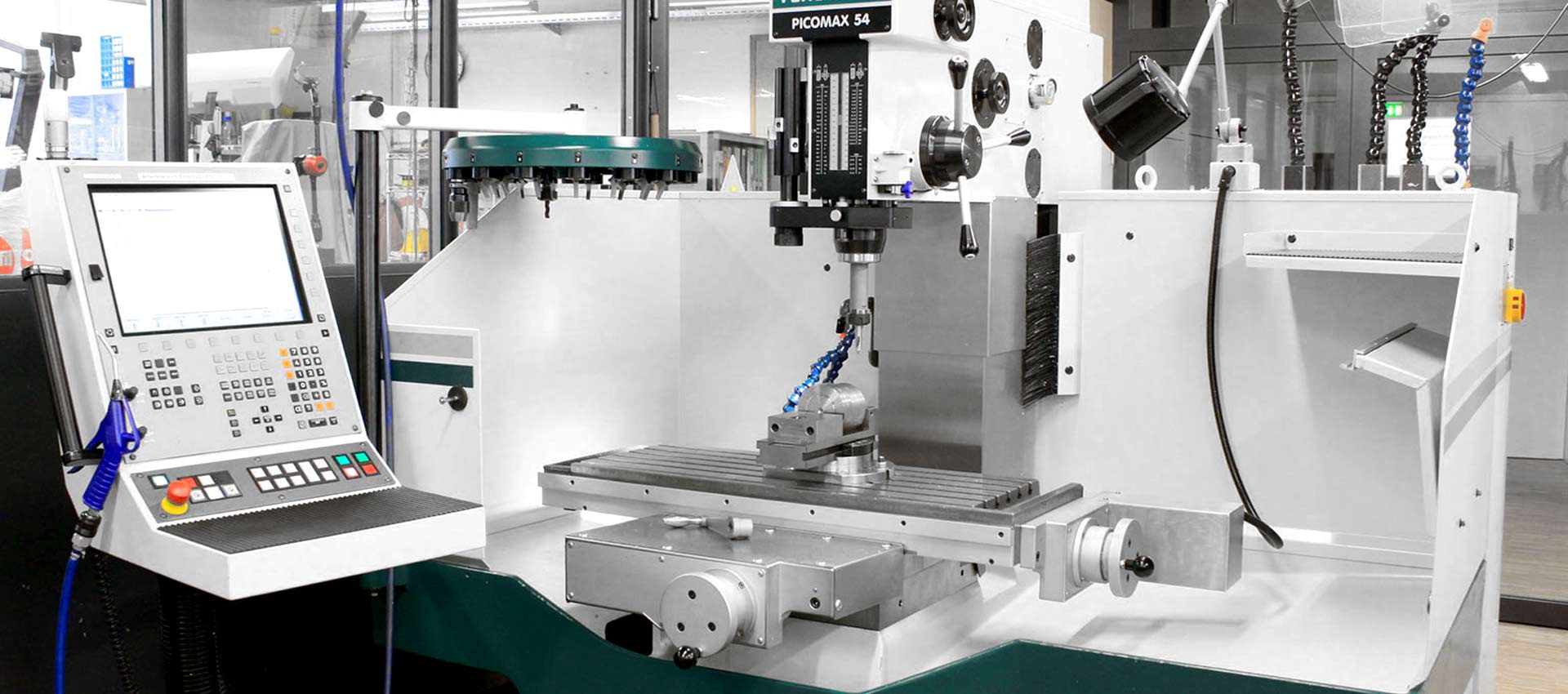

Conventional machining

Milling machine

Fehlmann Picomax 54

- Drilling capacity in steel: 20mm

- Spindle stroke: 160mm

- Boche speed: 100 to 7100 rpm.

- Useful table surface: 880 x 320 mm

Milling machine

Fehlmann Picomax 51 TNC

- Drilling capacity in steel: 20mm

- Spindle stroke: 160mm

- Boche speed: 50 to 9000 rpm.

- Useful table surface: 730 x 280 mm

Milling machine

Schaublin 53

DECKEL FP1

Cazeneuve Tower 360 Optica

Aciera 22VR drill

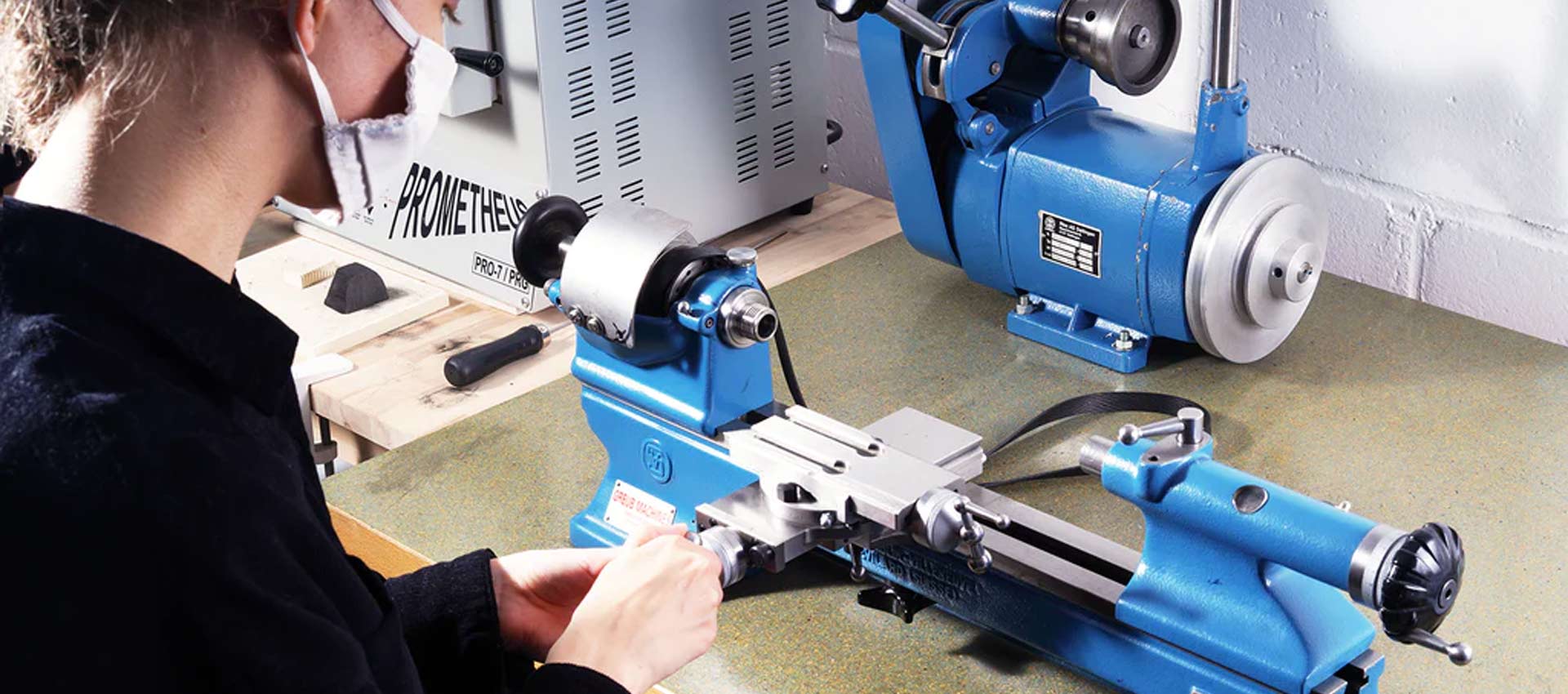

Micromechanics

- 11x Schaublin Tower 102-N W20

- Schaublin Tower 102-N W25

- Schaublin 70 watchmaker’s lathe

- 3x Grinding machine EWAG WS-11

- Technica 5500 grinding machine

- SIXIS S101 milling machine

- Milacron bench milling machine

- Sensitive milling machine

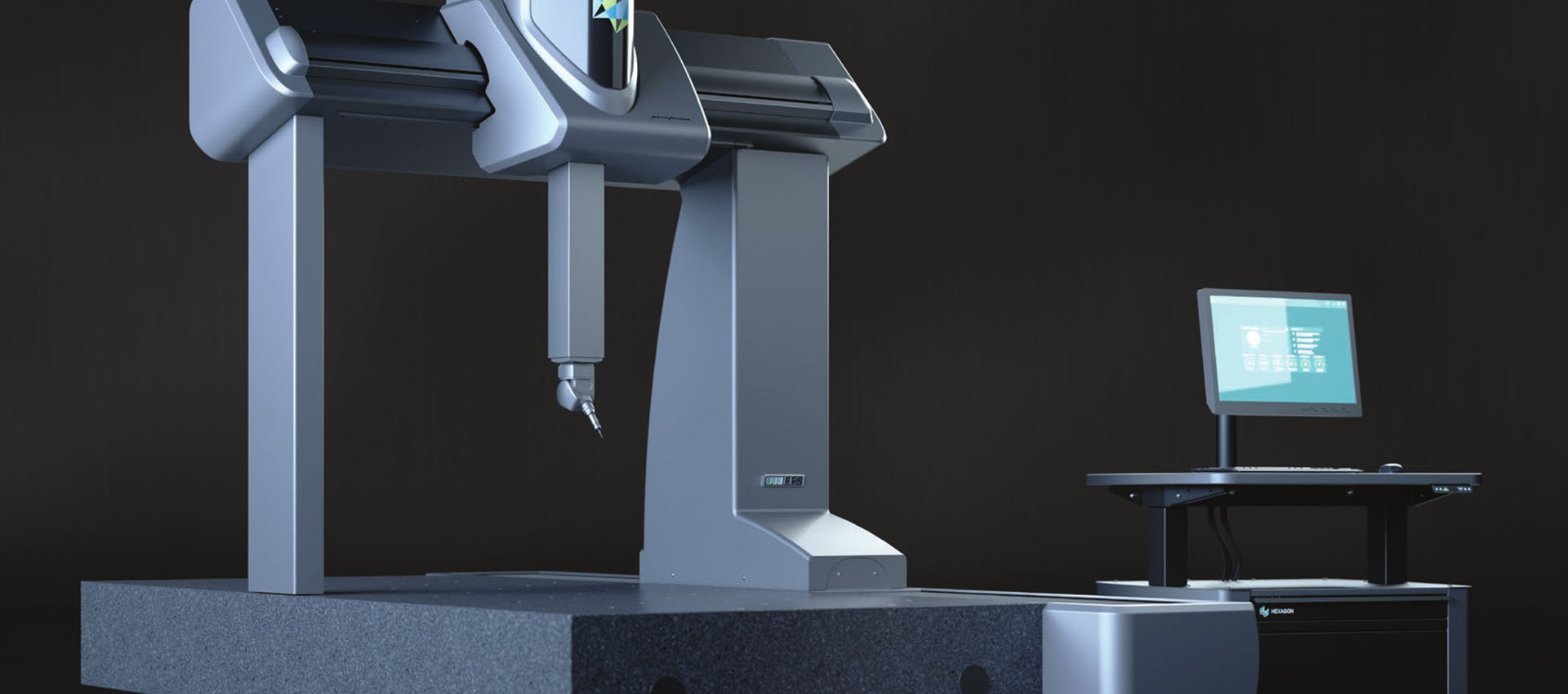

Means of control

3D measuring machine

Hexagon Global S Chrome

- Hexagon measuring head indexable every 2.5°.

- Probe ball from Ø 0.3 mm

- Probe changer with 6 positions

- Point-to-point control or scanning

- Stroke: 700 x 700 x 500 mm

- Max. part weight: 180 kg

- Accuracy: 1.5µ + 0.4L100

Optical measuring machine

JENOPTIK OPTICLINE C308

- Max. part diameter: ø800mm

- Max. part length: 300 mm

- Max. part weight: 20kg

- Accuracy ø: (1.5+D(mm)/200) µm

- Length accuracy: (4+L(mm)/200) µm

- Repeatability: 0.3 µm in ø and 1.2 µm in length

3D measuring machine

Mitutoyo Crysta Plus M443

- Stroke: 400 x 400 x 300 mm

- Resolution: 0.0005 mm

- Accuracy: E=+/- (3.0+4.0L/1000) microns

3D measuring machine – OGP Starlite 150

2x Measuring microscope – Marcel Aubert MA175S

Measuring columns – Trimos V6

Measuring probes – Heidenhain and Tesa

Control marble and granite

Treatments

- Tempering furnace

- Sandblasters / Microblasters

- Satin finishers / Polishers

- Trovalisation

- Paint booths

- Powder coating booth

Washing

PERO R1 washer

- Max. part size 530 x 320 x 200 mm 35 kg