pp:automation

Each special machine is created from your specifications to meet the specific requirements of your needs and your company.

Machines Automation

made to measure

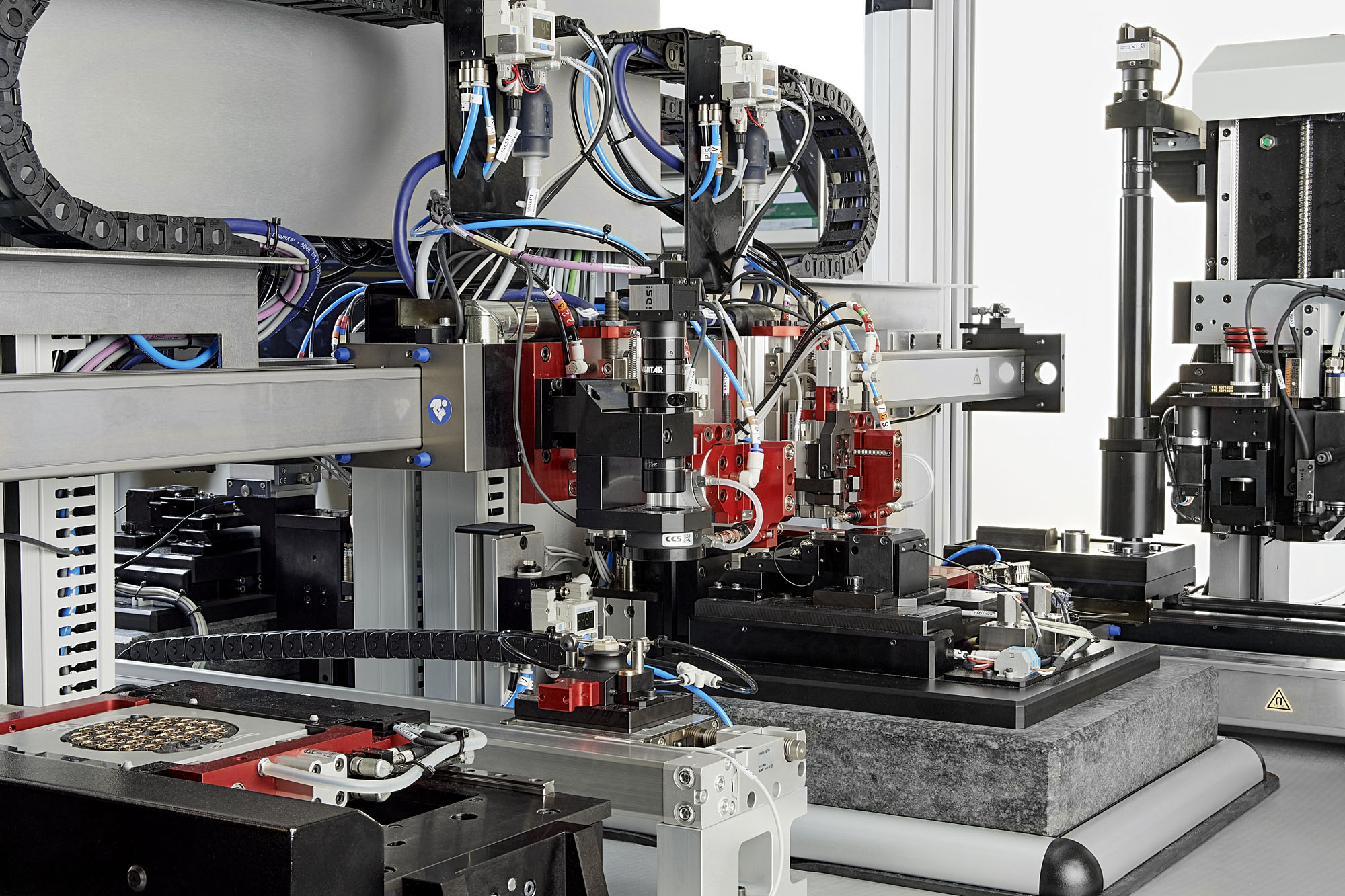

A recognized reference in microcomponent automation, we provide innovative solutions for industry, producing equipment with remarkable results, maximizing the price-performance ratio. We are mainly active in the watchmaking, high-tech precision and Medtech sectors.

- Assembly

- Chasing, Riveting

- Measuring and frolicking

- Laser welding

- Control

- Aesthetic and dimensional inspection

- Cleat installation

- Sorting

- Lantern

- Dimensional measurement

- Fracture testing

- Virolage

- Cut

- Raise, Shape

- Framing

- Release

- Wafer handling

Modular assembly machine

The benefits:

- Palletizer accessible during production

- Operator-free series changeover

- Coupling with other machines

Configuring your machine :

- Heads for up to 8 grippers

- Several cameras

- Up to 4 palletizers

- Up to 4 flexible power supply modules

- Up to 3 vibratory bowls

- A rotary table

- Digital press

- A 180° turning module

- An infeed/outfeed conveyor

Cannon pinion indenting equipment

This semi-automatic equipment is designed to adjust the center pinion by indenting the cannon pinion surface. The precision of the operation is achieved thanks to the high-precision mechanics and the integration of a closed-loop vision system. The indenting process involves an initial deformation performed by the 2 knives. A vision algorithm then drives a second deformation to achieve the desired precision.

- Repeatability: +/-1 µm

- Cycle time: < 13 sec. /part (loading in masked time)

- Dimensions : W 800 x D 600 x H 300 (650 with display)

- Weight: 177 kg

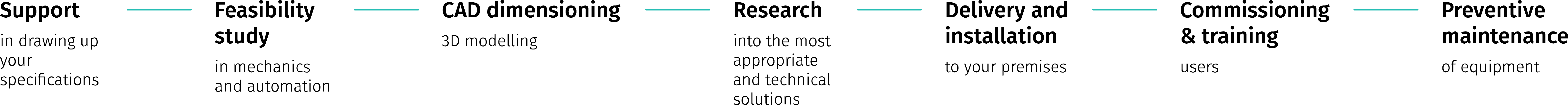

Our project management process

Customer benefits

- Simplified communication A single point of contact from start to finish

- Development efficiency Strong capacity for innovation

- Guaranteed results Derisking through feasibility analyses. We contractually guarantee our results

- Sustainable solutions Our customers' high standards are matched only by the robustness and reliability of our equipment.

Our team

Our project managers are fully conversant with the development, fine-tuning, validation and documentation phases, so that our customers can rest assured that their projects will be carried out with complete peace of mind.

A team of over 20 highly motivated engineers is looking forward to meeting your new challenges.

Our unique machining capabilities and meticulous finishing contribute to the success of our reputation and the pride of our achievements.